2017-01

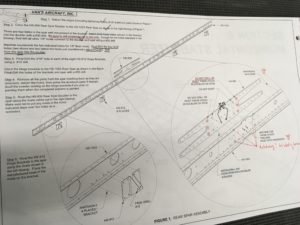

Page 6-2 to 6-5 Rear Spar

Preparing the rear spar, deburring, straightening, final drill and match drilled some parts. Parallel to the deburring I took the training projekt (Vans Tool Box and the flap training kit). My friends Frank Goehner and Ernst-Otto Rehm are very helpful giving me hands to help at some difficult to reach places and by having fun with the build process. I´m glad to have them as friends – not only for some help :o)

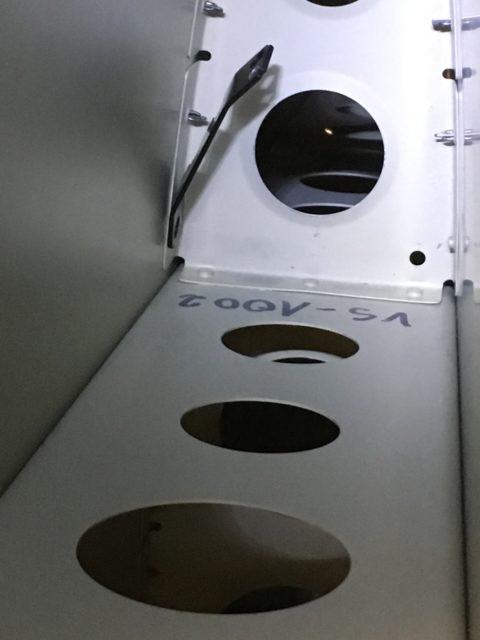

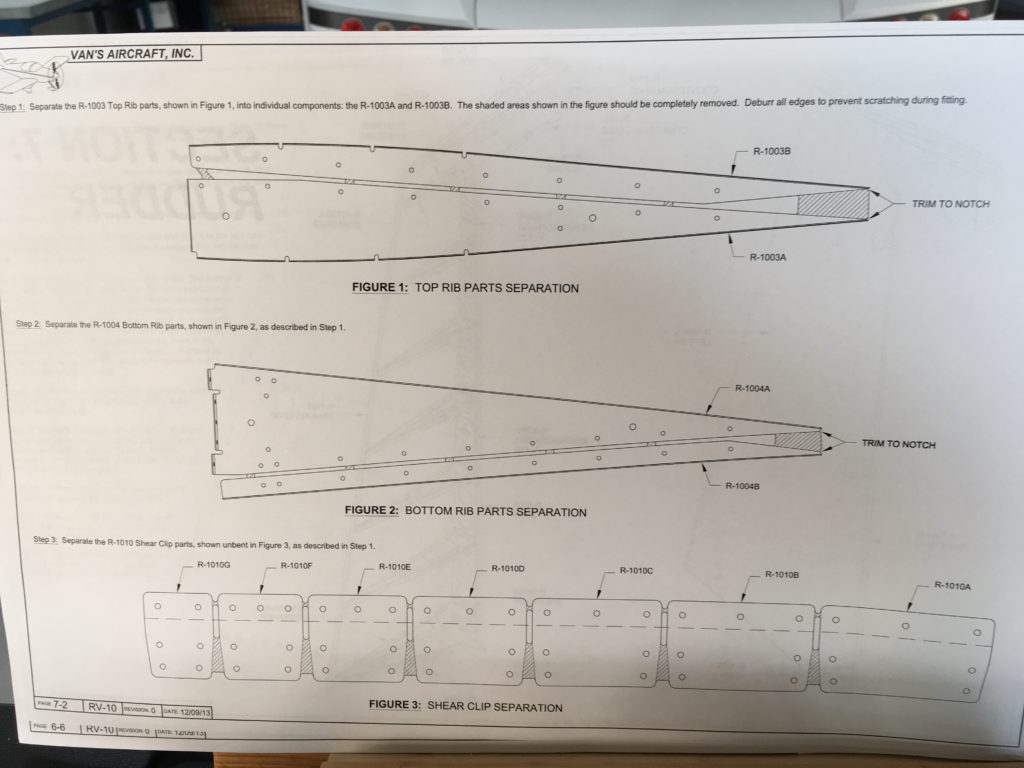

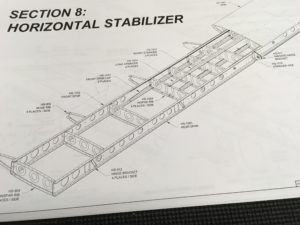

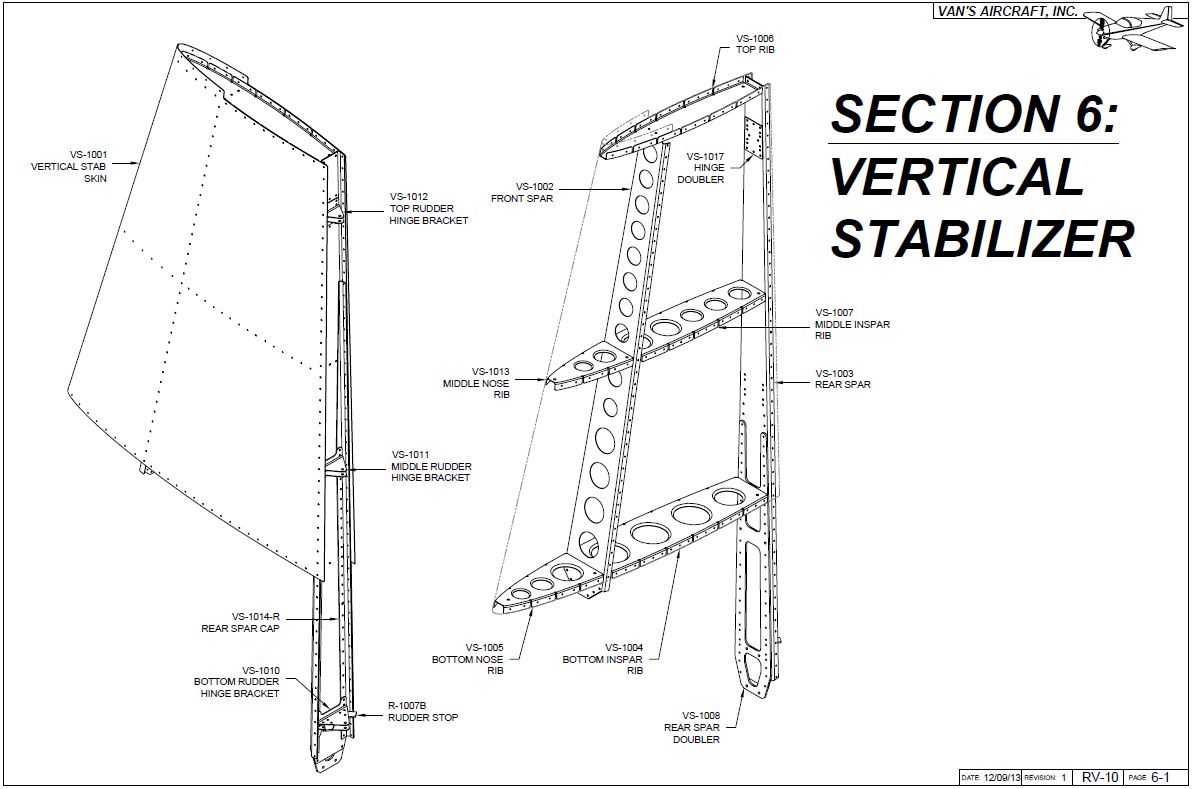

Deburred all the skeleton parts of the vertical stabilizer, straightened the VS-1008 rear spar doubler, clecoed all parts together and final drilled all #30 holes. Peeled of the blue tape from the skins inside and on the outside only there, where to work on the prepunched holes with a straight edge and a soldering iron. Clecoed the skin to the skeleton and final drilled all the holes common to the skin, exept the holes for the HS and VS fairings.

HS = Horizontal stabilizer, VS = Vertical stabilizer

VS-1003

vs reinforcement plate

match drilling

Clecoes – the magic thing

Bohrungen gesenkt für Nieten

Teile fixieren, dreimal auseinander und zusammen

rivet hole countersink

peeling of the blue protection

Radius schleifen VS nose rib

Helping hands

Ernst-Otto Rehm

Frank Goehner

Deburring VS parts

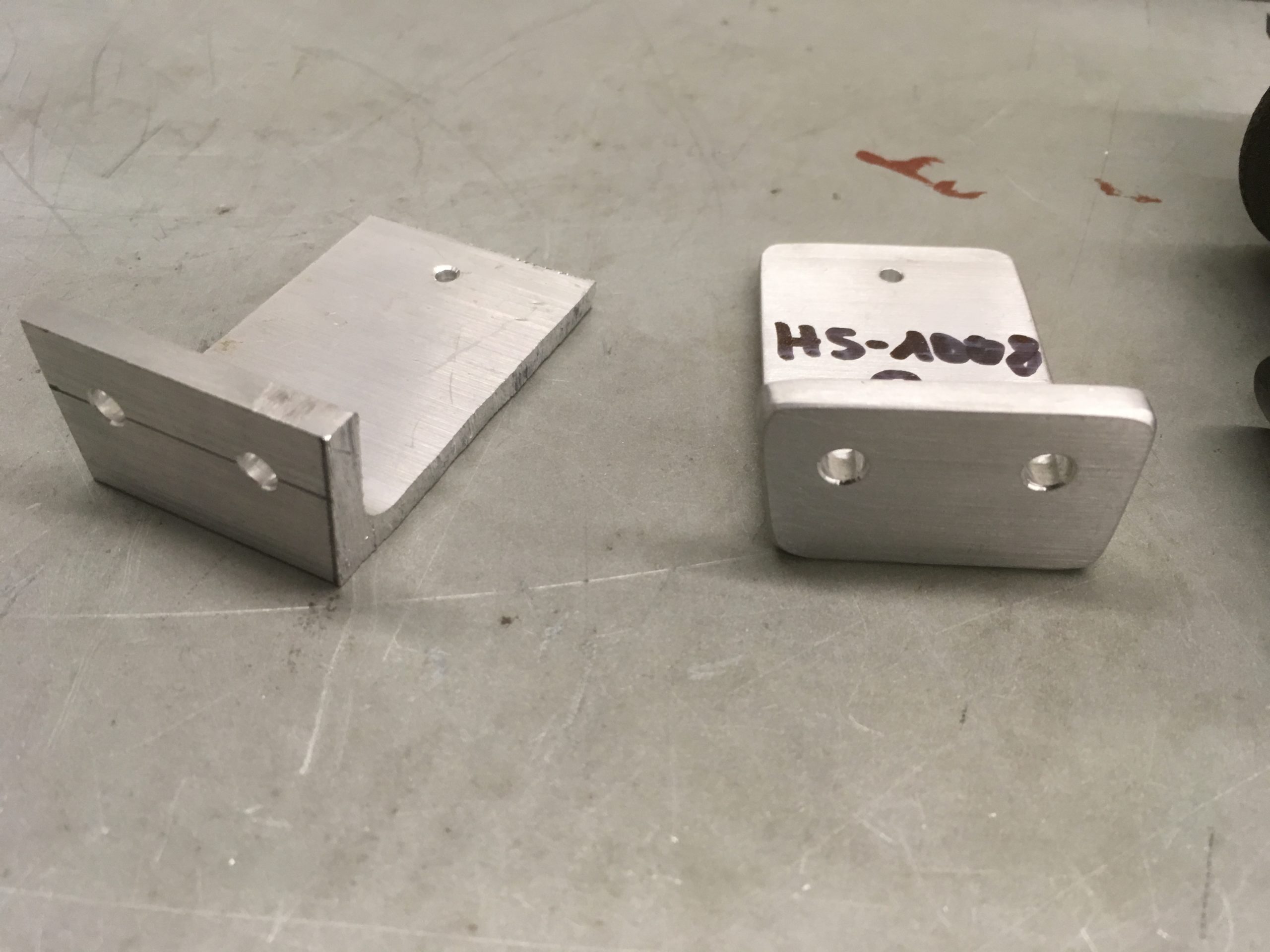

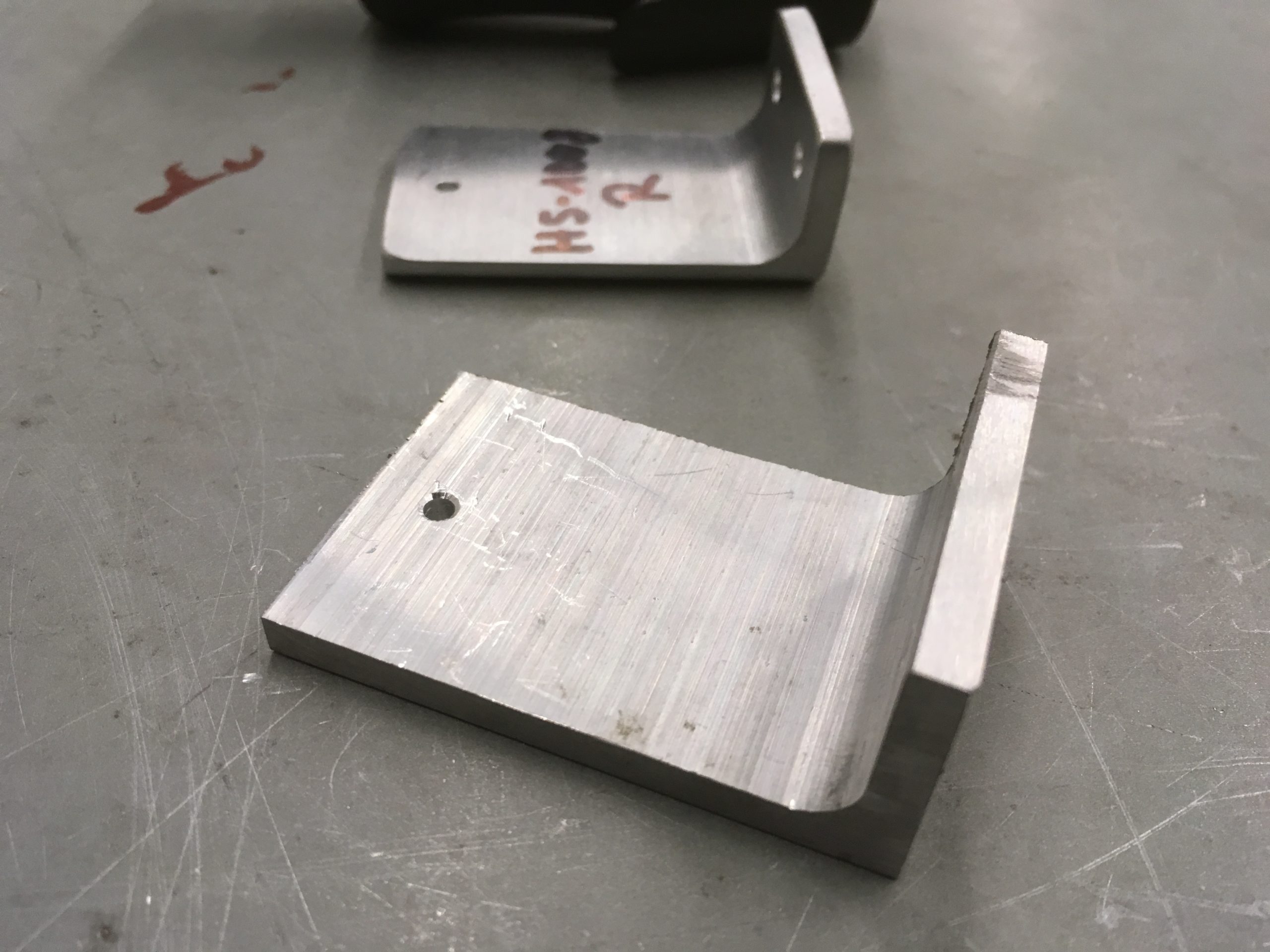

VS rear spar caps

VS-1008 reinforcement plate after straightening

19.01 – 24.01.2017 = 14,5h

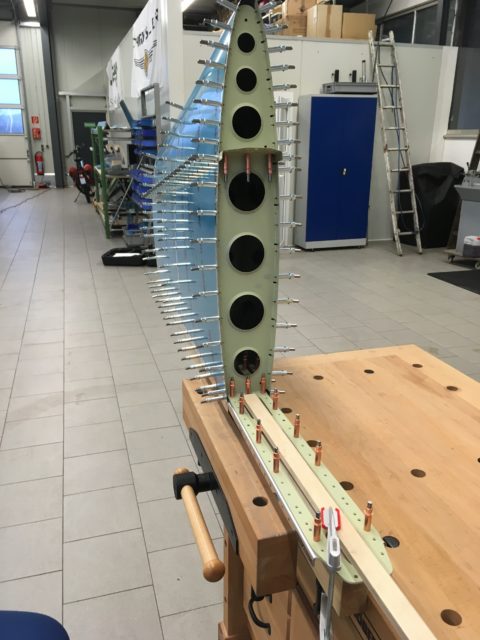

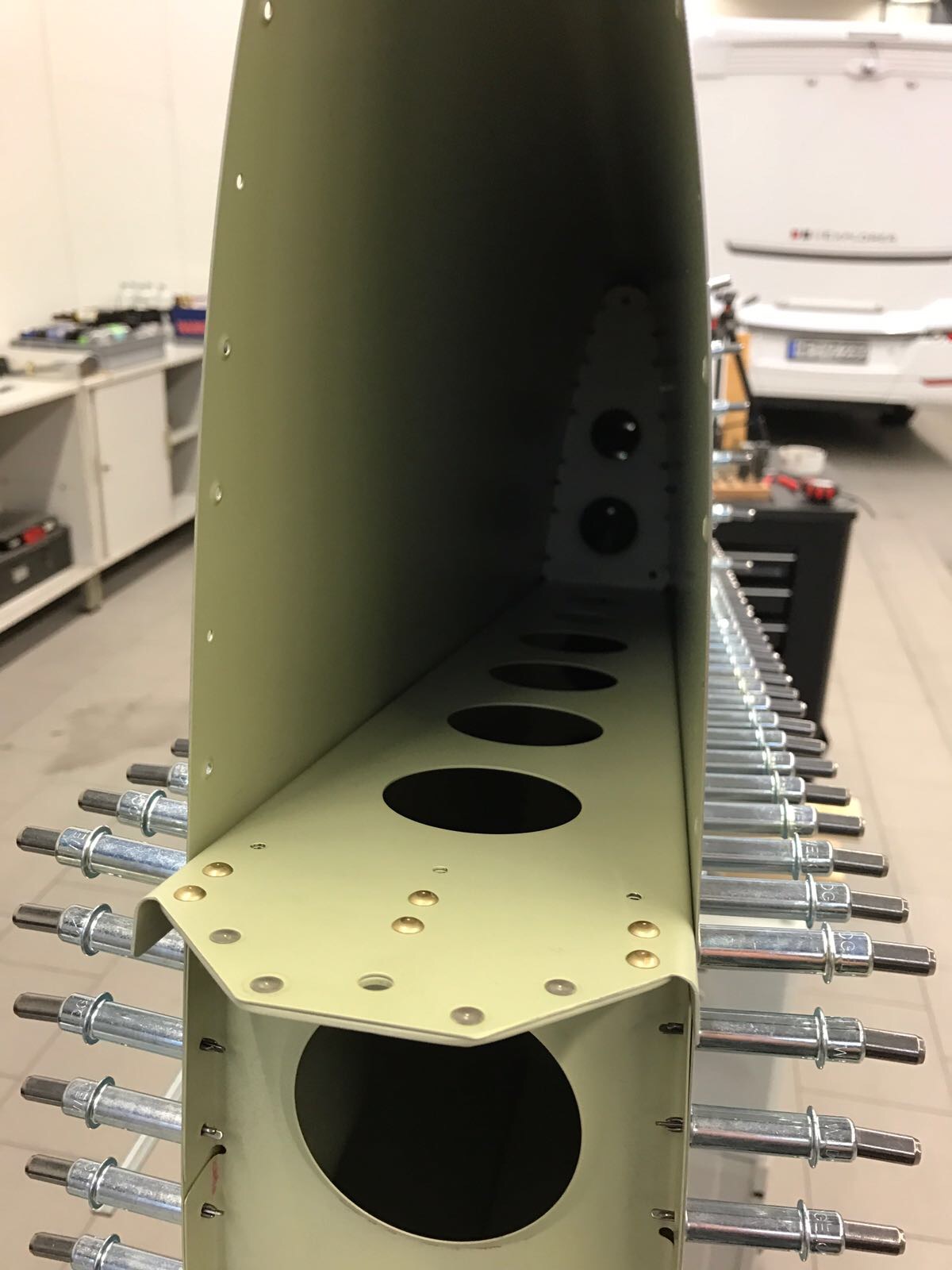

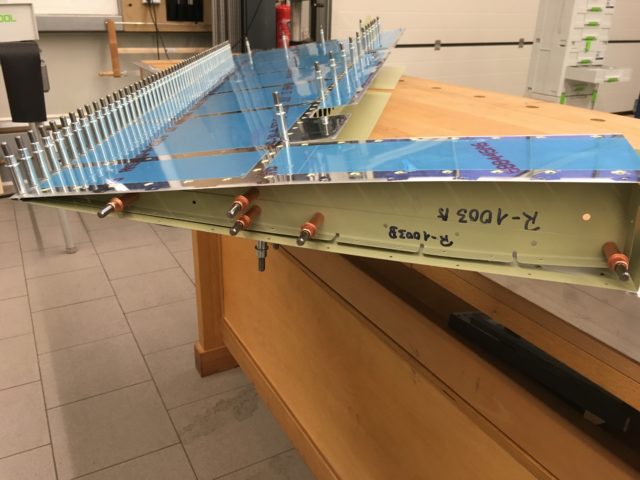

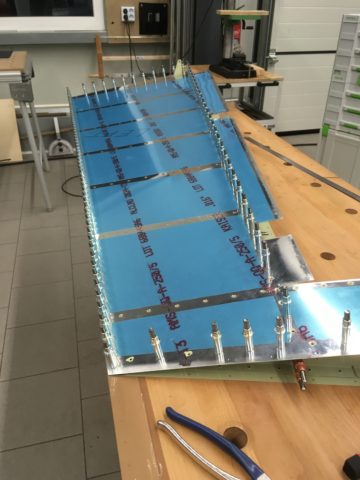

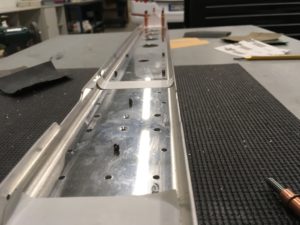

Parts priming, Assembling the VS skeleton

Cleaned all VS Parts, assembled and riveted them together. I checked every manufatured rivet head for correct size with the rivet head control tool. To be able to run some wires through the vertical stabilizer for later use (i.e. Nav Antenna or similar), I glued a PVC-Pipe inside the VS Skin with a PU glue from Würth „Klebt+Dichtet“.

Primed with SEEVENAX Primer

VS-Parts ready for assembly

VS-Rear Spar before riveting

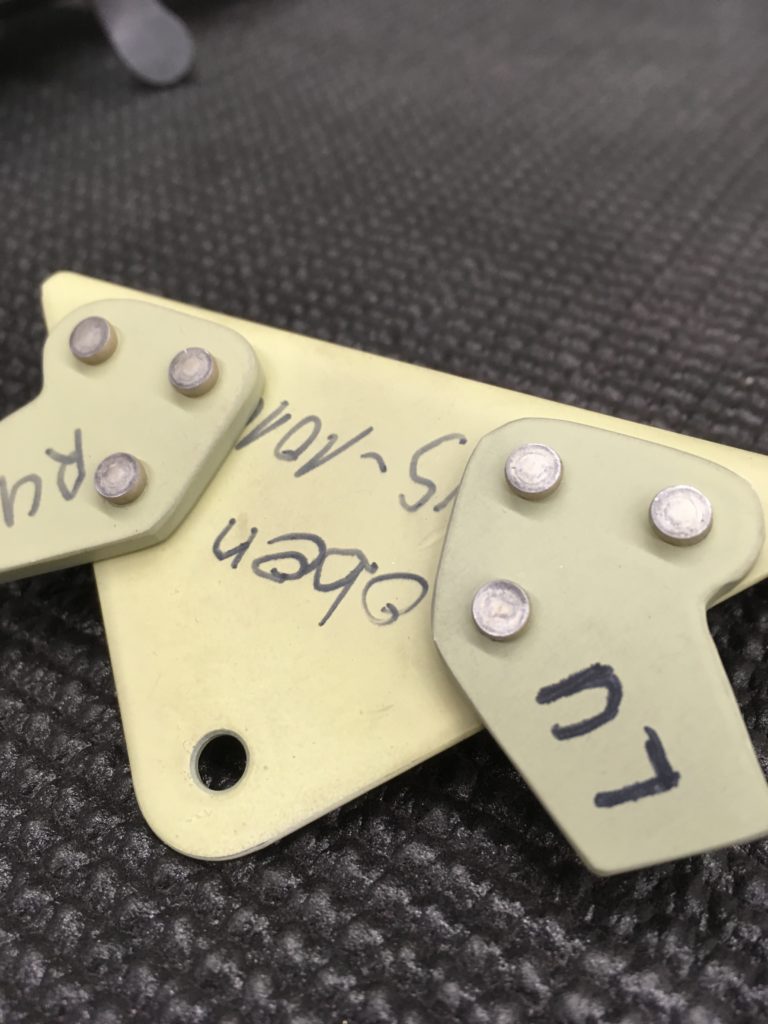

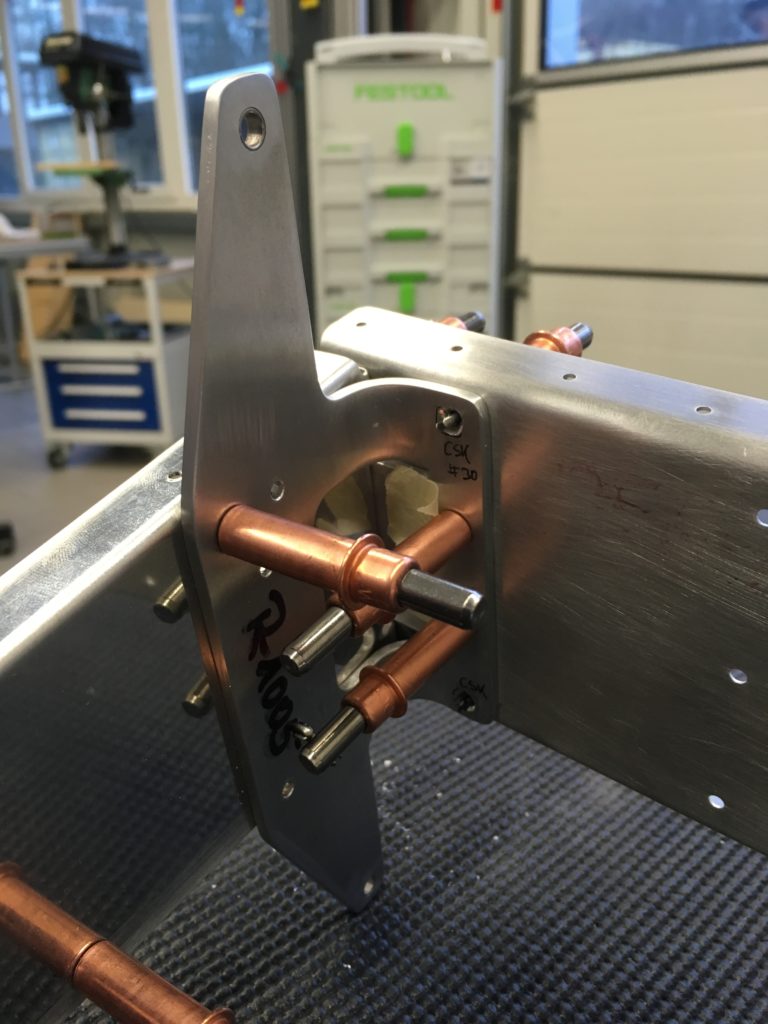

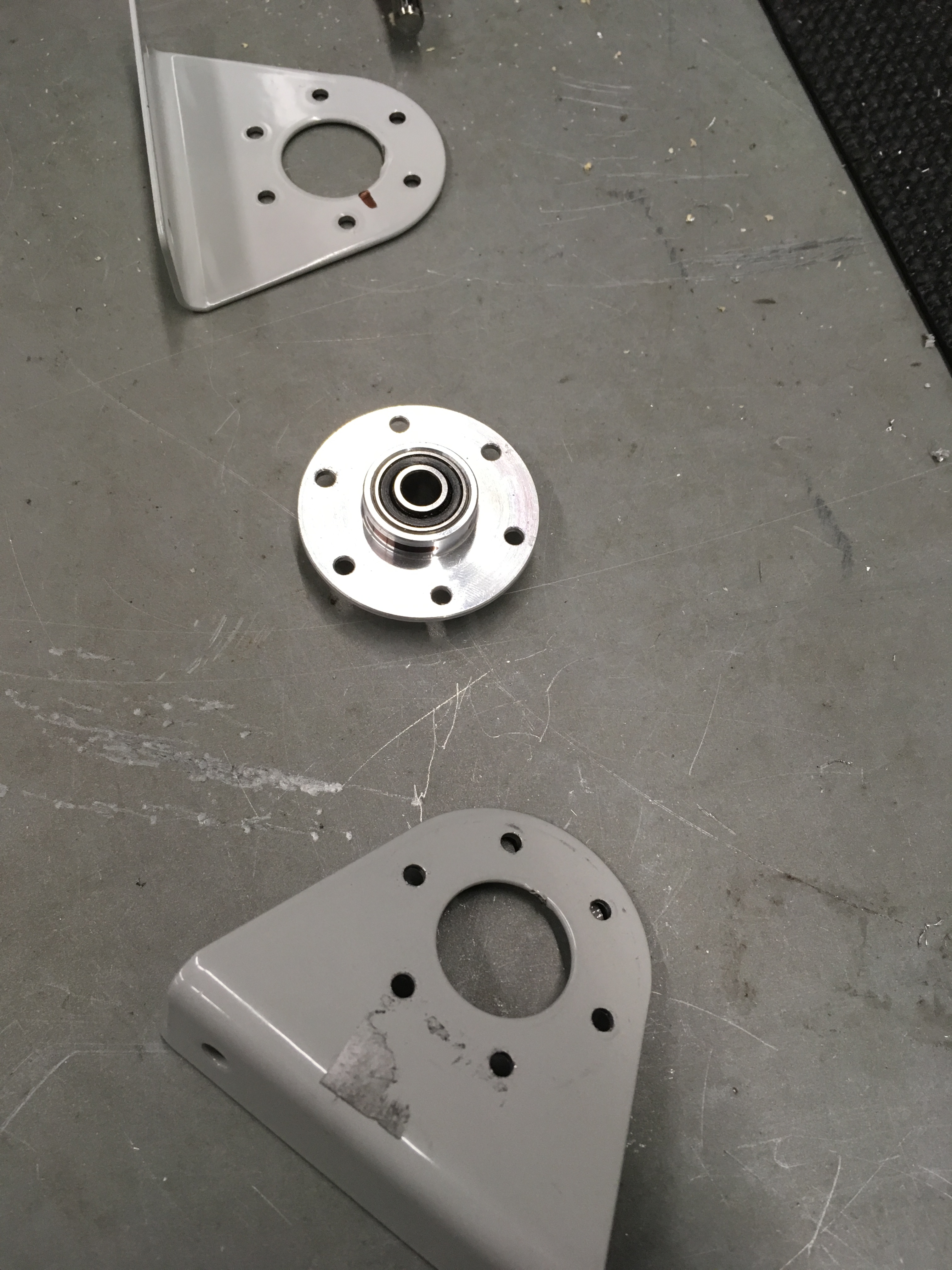

Rudder Stop bracket

Rudder Stop Bracket riveted

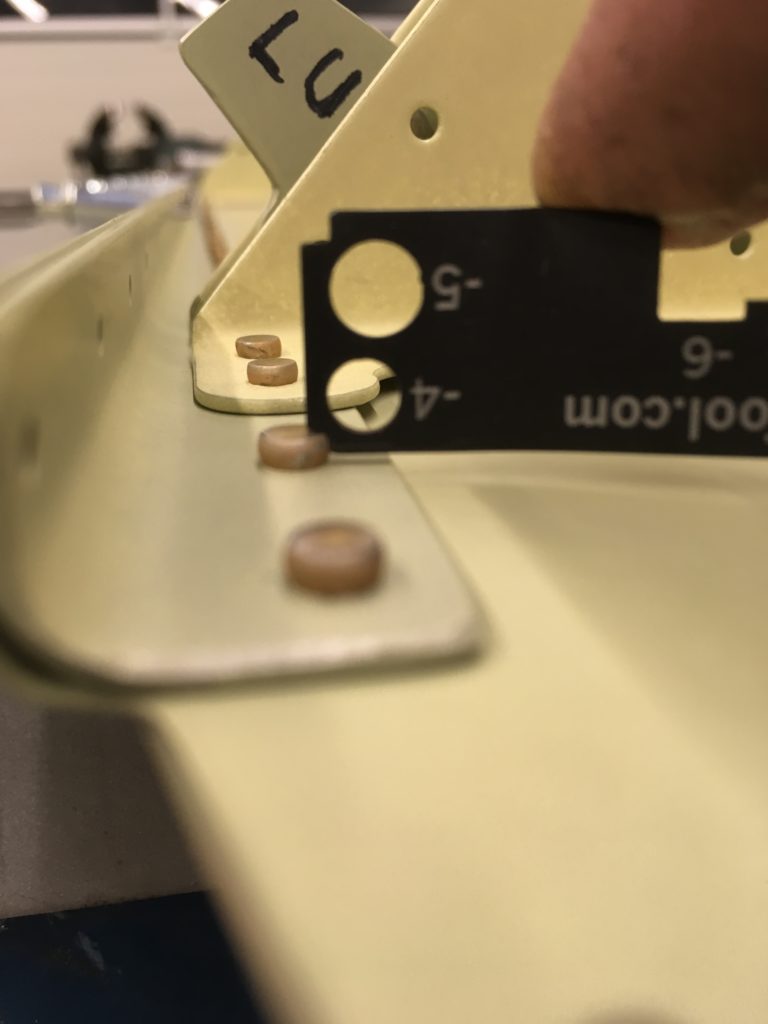

Gauge checking the set rivets

Diameter check = OK

Skeleton primed and ready for riveting

VS-Spar riveted

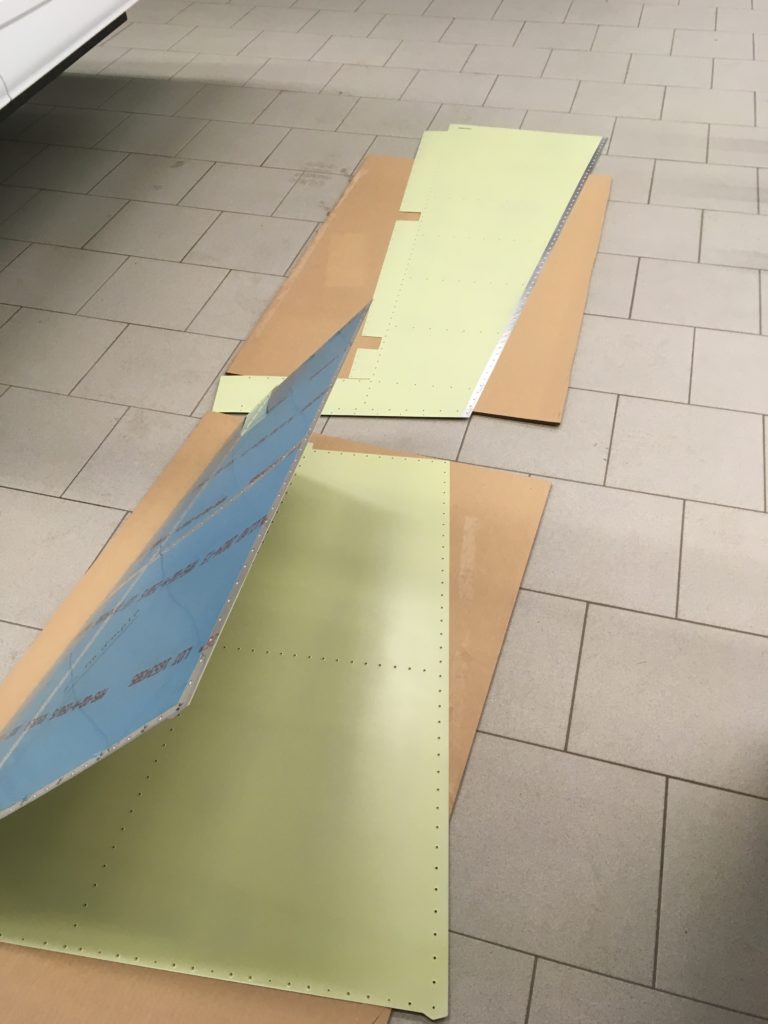

Vertical Stabilizer and Rudder Skins primed and ready for riveting

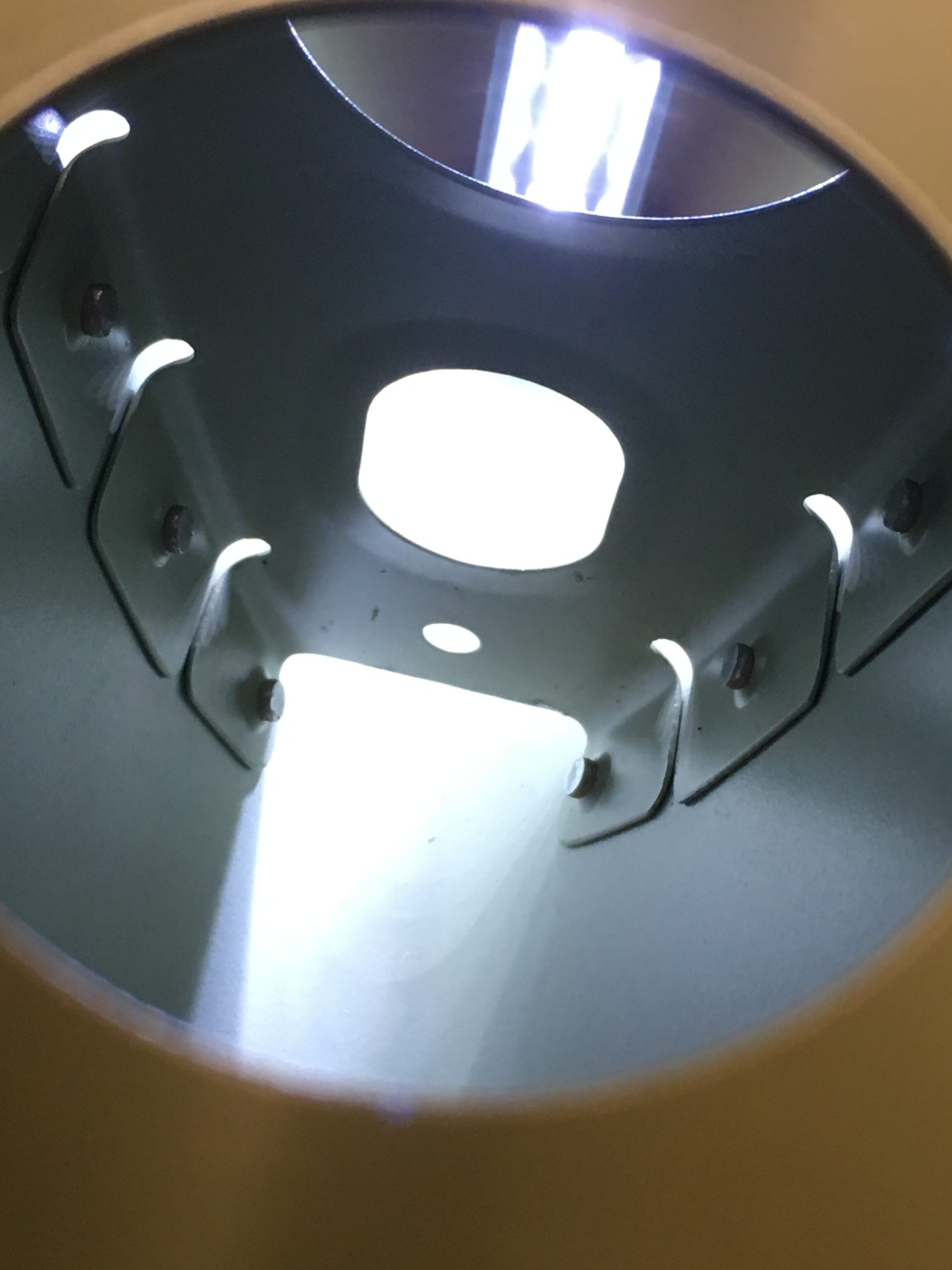

Cable tube glued in place

Würth „Klebt + Dichtet“

VS-Nose Rib Cut Out

18.02.2017 – 22.02.2017 = 12h

2017-02

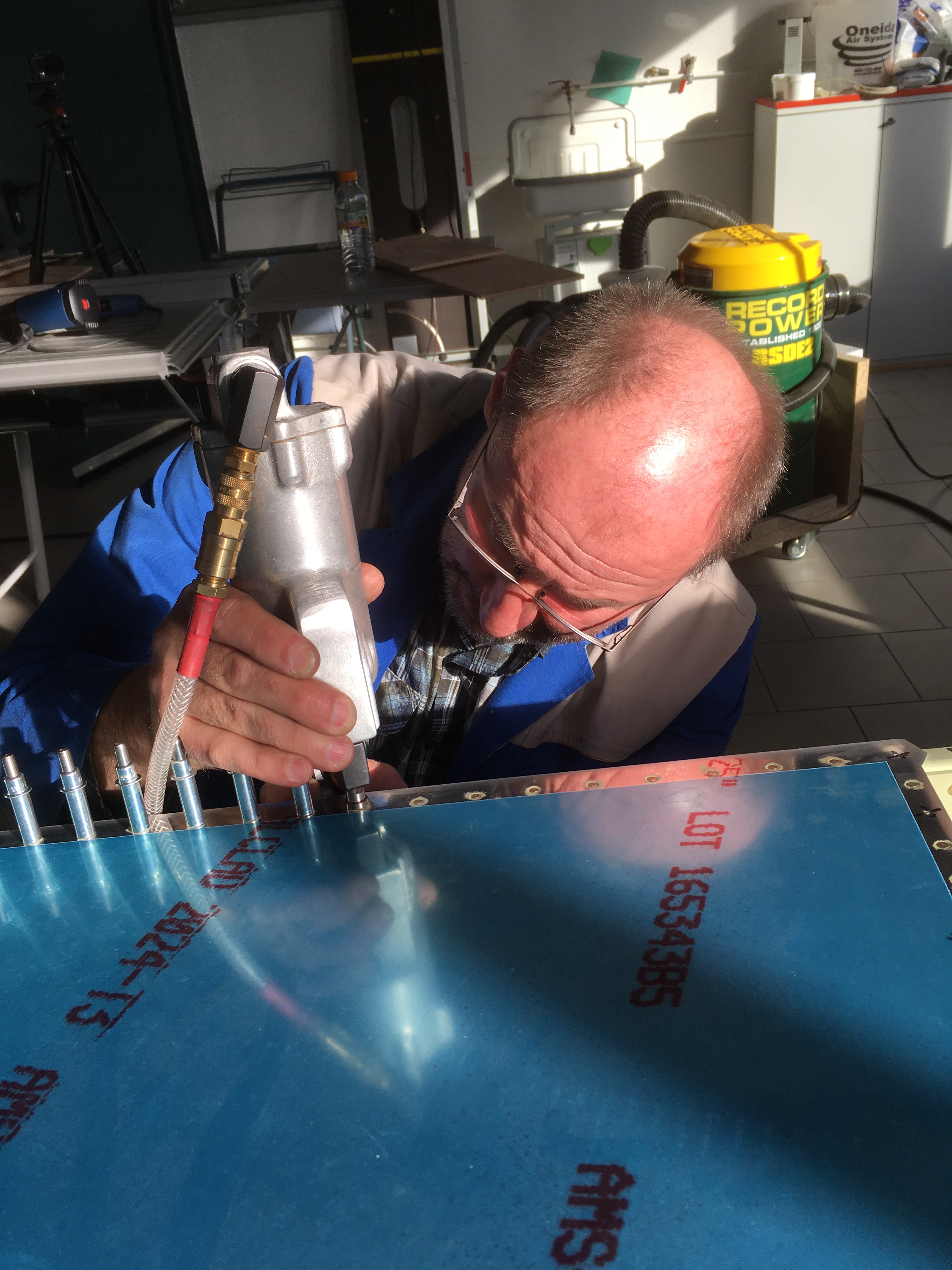

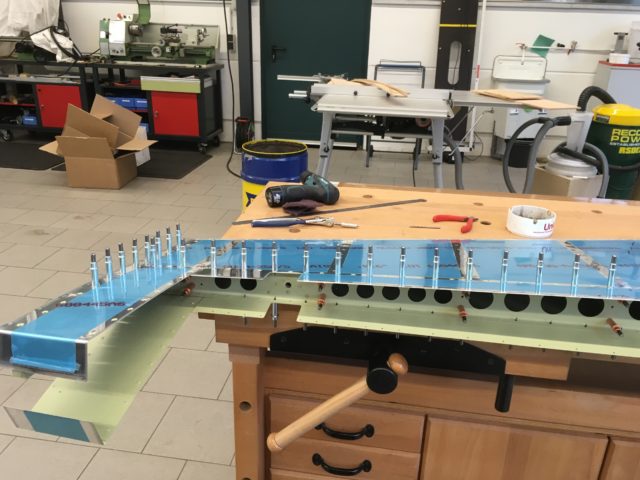

Riveting the Vertical Stabilizer Skin to the skeleton with the Pneumatic Squeezer.

Before closing the VS Skin my building mentor Christian Tank came along and checked everything to be properly riveted and assembled and said: „Du baust sehr genau“ (You´re building very accurate)….what made me a little bit proud of myself 🙂

You also may want to see the Video down on the bottom of this page…

My building mentor: Christian Tank

Christian Tank is the CEO in the company, he took over from his father Wilhelm Tank. His company:

Wilhelm Tank GmbH & Co Mariensiel KG

Flugplatz 1

26452 Sande

VIDEO: How Frank and me do the riveting process together on the vertical stabilizer

Begin the riveting process my friend Frank Goehner was very helpful and we managed the riveting process really good together.

- Vertical Stabilizer start: 19.01.2017

- Finished: 01.04.2017

- Hours total: 26,5