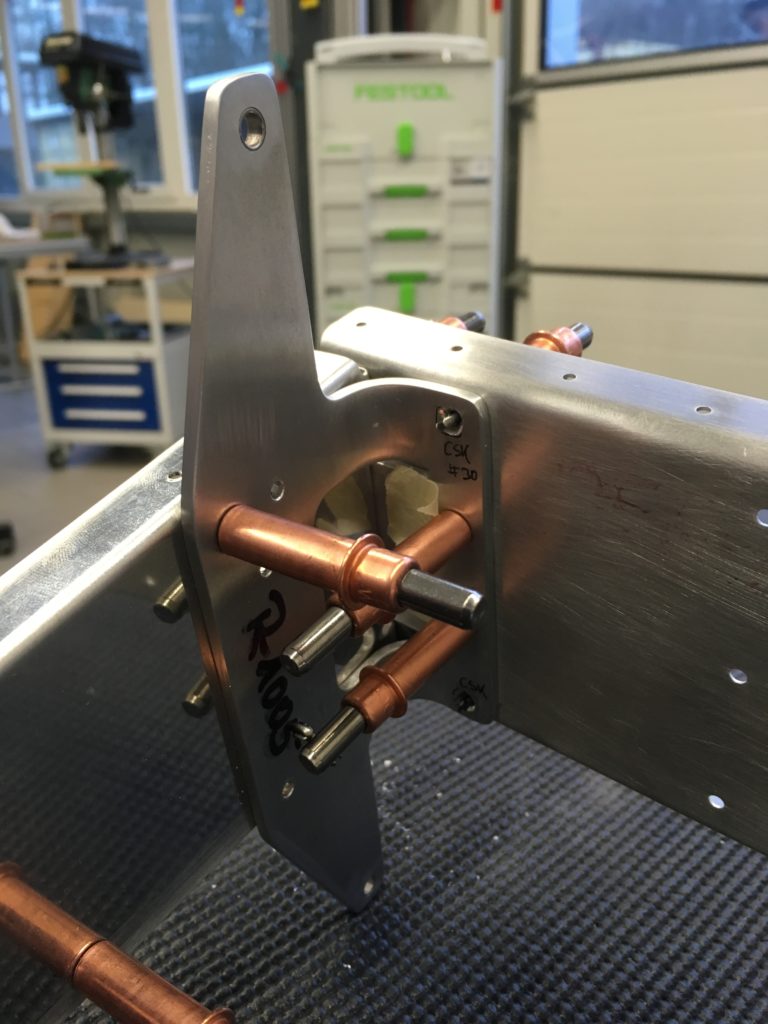

In this section you will see my self made (DIY) dimple frame DRDT-2 in his final version which I finally will use the whole building process. I am proud, that my version is functioning so far. Looking forward to use it for many times which will safe me a lot of hours!

Nach unten navigieren

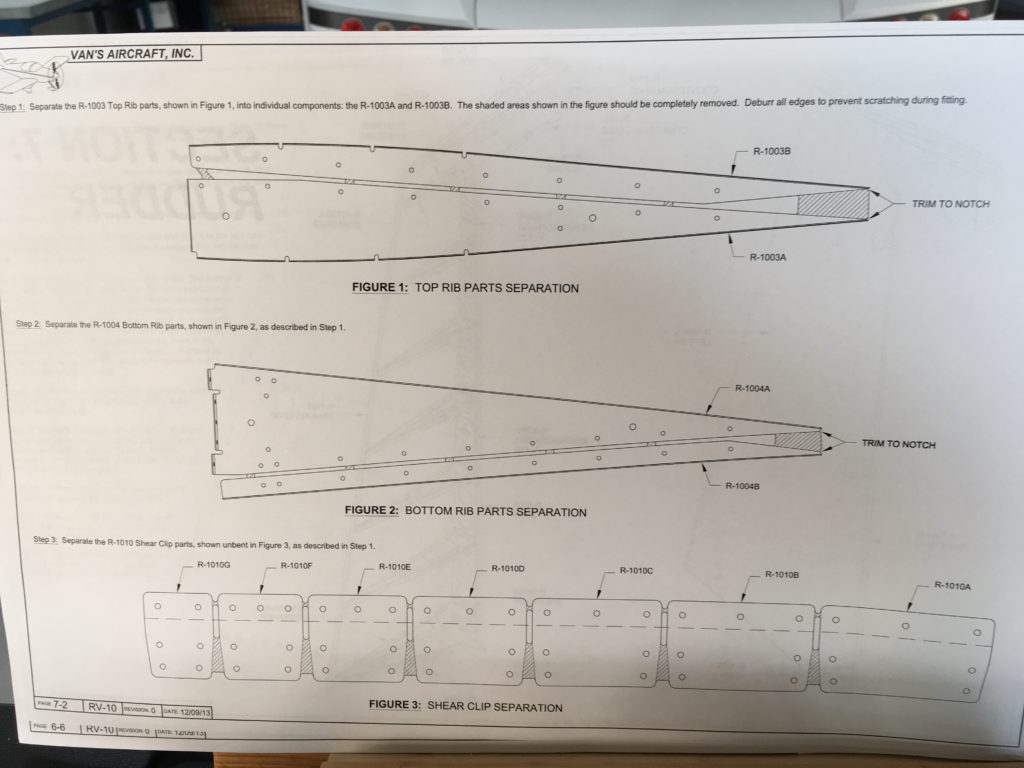

Page 7-2 to 7-6

Preparing all the Rudder parts

Before putting them together, you have to prepare all the parts to fit together, so all edges has to be deburred, some parts have to be cut to almost smaler parts like the R-1010 Rudder ribs.

This is taking a lot of time and sometimes a boring thing to do, but it is an essential work, because with this it is possible to ensure a long lasting airframe over many years of flying.

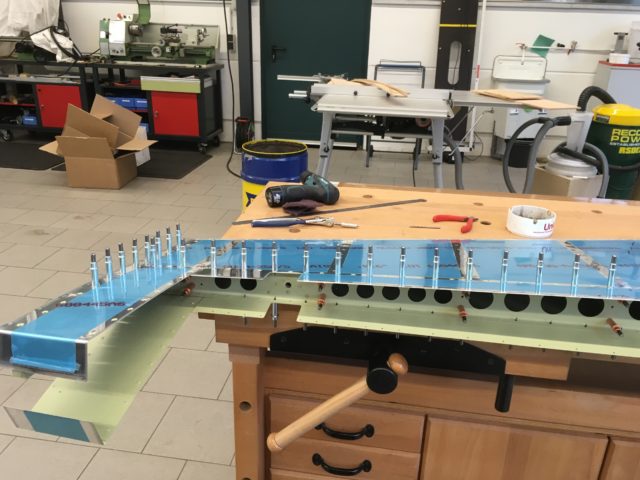

Dimpling the Rudder Skin

Selfmade Dimpletframe by Peter Aringer

Dimple detail Rudder Skin

Dimple detail row Rudder Skin

Dimple Frame with Squeezer

Dimpleframe head

Dimpleframe head detail

Rudder rib dimpled

Rudder skeleton

Rudder Skin scuffed with scotch brite pad

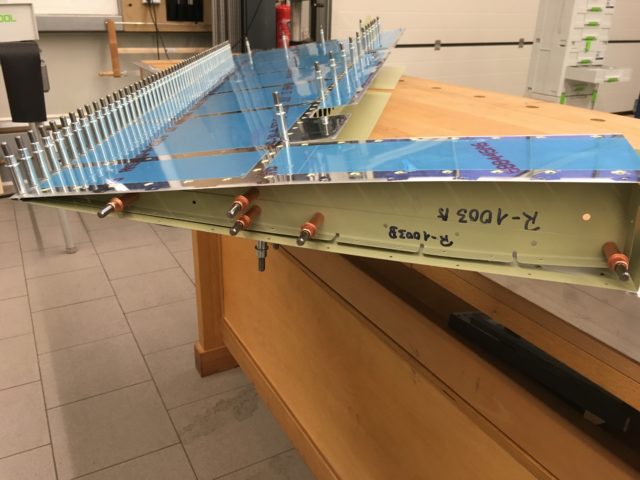

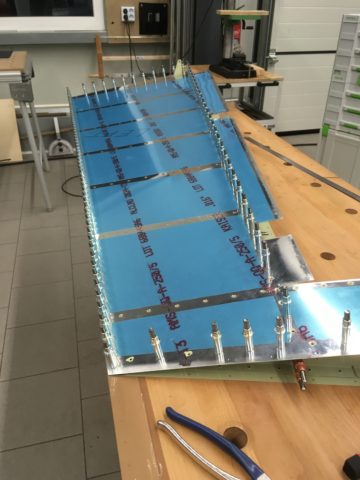

Rudder complete cleoed together

Rudder skeleton clecoed

Rudder Skin blue film removed

Rudder skeleton on the left skin

Rudder skeleton on the table

Rudder skeleton

Rudder cable arms

Rudder lower rib

Rudder parts ready for priming

Cutting instructions for the Rudder ribs

Riveting instructions for the Rudder ribs

Rudder Ribs befor cutting

R-1005 before preparing

Rudder rib parts

Rudder parts to be prepared and cut to size

Page 7-7 to 7-12 Riveting the Vertical Stabilizer, Rolling the leading edge, trailing edge finish

Now the exiting process of assembling all the prepared parts of the vertical stabilizer begins.

When I clean the parts for priming, it is essential to mark the preped parts in the exact same way they were marked before!!

At the top vs-rib I had a slight missalignment an had to fix this with drilling some new holes in the R-1008A and R-1008B top ribs.

The whole process of riveting all the VS parts together turned out to be very exiting. The most exiting thing here was to bend the leading edge in a correct manner to not screw this up an make some niks in the skins while bending them.

Rudder metal work is finished. Some work to do on the upper and lower fairings on the rudder. Will return later on. 13.05.2017

Nach oben navigieren

Rudder start: 02.February 2017

Finished: 13.Mai 2017

Hours: 25